Sodium silicate admixture systems eliminate free water and capillaries

by Scott Bergsbaken

In 1999, the U.S. Environmental Protection Agency (EPA) issued its final regulations designed to control volatile organic compound (VOC) emissions from architectural coatings.1 The new regulations essentially forced coatings and adhesives manufacturers to use water-based chemistry in lieu of the previously employed solvent-based systems. Unfortunately, the new water-based systems were very sensitive to moisture conditions. Floor moisture and damaged flooring soon became a major problem for the construction industry.

Concrete and Moisture

A typical 4000 psi (35 MPa) concrete mixture contains more water than is needed to hydrate the portland cement. While this water is needed to facilitate mixing, pumping, placing, and finishing, it also can weaken water-based adhesive systems as it migrates to the surface and is trapped beneath relatively impermeable flooring materials.

Flooring manufacturers typically require that the concrete reaches an internal RH of 75 to 85% prior to application of moisture-sensitive coatings or adhesives. Getting to that point is affected by numerous factors, including:

- Time — It takes time for concrete to dry. Some within the flooring industry use the guideline that a favorable relative humidity (RH) in the concrete requires 28 days per 1 in. (25 mm) of concrete thickness;

- Ambient temperature — Drying rate increases with temperature;

- Ambient RH — Drying rate decreases with increased ambient RH (ambient RH is the most important factor affecting the drying rate);

- Rewetting — Precipitation, curing water, or cleaning water will penetrate the concrete through the capillary system and extend the drying time dramatically; and

- Material storage — Construction materials resting on a concrete surface create a vapor retarder, reducing the drying rate as water vapor condenses at the surface.

Waiting for a slab to dry is expensive, but closing in a building early to prevent rewetting and allow dehumidification is also costly. It’s impractical to expect subcontractors to bring materials into the building only when needed. While adding vapor retarders to the surface of concrete (for example, epoxy coatings or sheeting) is an alternative solution, surface treatments can also add time and cost to a project.

An Intrinsic Solution

Another approach to this problem is to reduce the free water and capillaries in the concrete. Pozzolans are capable of doing this; however, they are also relatively slow acting. An alternative that can quickly achieve both goals is to use a water vapor retarding admixture (WVRA) such as sodium silicate. Sodium silicate has a long history in the construction industry. It’s been used in cement grouts since 1911,2 and it’s been used as a concrete admixture for decades. A modern sodium silicate admixture meets the requirements for Type S (specific performance) concrete admixtures per ASTM C494/ C494M, “Standard Specification for Chemical Admixtures for Concrete.”

As with pozzolans, a properly formulated sodium silicate admixture reacts with the CH and the free water to form C-S-H gel3— the building block of concrete. The reaction can yield upwards of an additional 300 lb of C-S-H gel per 1 yd3 of concrete (180 kg/m3).4 This additional C-S-H gel serves as an internal curing medium, and it helps to keep all but the largest of the aggregates suspended in the concrete. As a result, bleed channels and pores are drastically minimized.

Quality Assurances

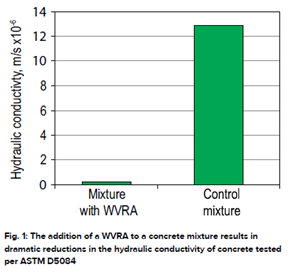

WVRA technology is verified through quality assurance testing. The industry-standard quality assurance program includes the testing of 4 in. (100 mm) diameter concrete cylinders per ASTM D5084, “Standard Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter.” Test cylinders are produced in the field, cured in the laboratory, and tested by hydraulically pushing water through the length. The hydraulic conductivity of the test specimen is indicative of the presence of a WVRA in the concrete (Fig. 1), as the admixture can cause more than one order of magnitude improvement in conductivity.

Field moisture testing has been a significant challenge for WVRA manufacturers, as there is no recognized, quantifiable test method for evaluating moisture-mitigated concrete slabs (that is, slabs modified using a topical epoxy or slabs cast using concrete containing an integral admixture). The standard moisture testing methodology for concrete slabs is ASTM F2170, “Standard Test Method for Determining Relative Humidity in Concrete Floor Slabs Using in situ Probes.” This typically involves drilling a hole in the concrete and placing an RH probe in the created cavity. Most flooring manufacturers recommend the use of this test method in their installation guidelines. If the test indicates an RH level above a specified limit, a topical moisture mitigation system is typically required. No further moisture testing occurs after the application of the mitigation system.

Shortly after construction, the C-S-H gel formed by a WVRA removes free water from the mixture but will release that moisture to any constituent of the system making a demand on it.5 With enough time and appropriate temperature, the C-S-H gel will harden and chemically bind the water. However, most projects can’t be delayed to wait for this to occur, so the flooring installation usually takes place prior to the time the in-place probe indicates an acceptably low RH.

ASTM D4263, “Standard Test Method for Indicating Moisture in Concrete by the Plastic Sheet Method,” is not a quantitative test. It involves placing a plastic mat on the slab for 72 hours and looking for physical signs of moisture. The test is conducted when the surface temperature and ambient conditions are within established parameters for application of the coating system. Some WVRA manufacturers have modified this test and found a way to make it a quantitative, repeatable test.

A slab can be tested if the ambient RH and temperature provide a positive vapor drive from the slab into the space above. A surface moisture meter is placed on the slab and an initial moisture reading is taken. The slab is then covered with a low permeability plastic sheet, and foil tape is applied around the sheet’s perimeter to complete the seal. This covering is removed after 72 hours and a second reading is taken to determine the change in moisture over the 72-hour period. An increase of over 0.5% shows a moisture problem and that corrective action is required prior to the installation of floor covering.

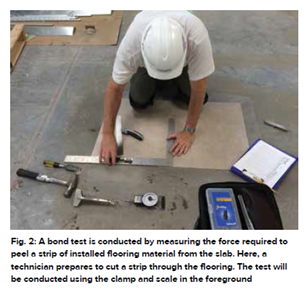

Additionally, a bond test is conducted to ensure proper adhesive and technique are being employed. WVRA manufacturers have developed a test that offers repeatable, quantifiable results.

Bond Testing

First, a representative sample of flooring is installed. Vinyl composition tile (VCT), for example, is typically provided in 1 x 1 ft (0.3 x 0.3 m), but sample sizes of other materials can range up to 3 x 3 ft (1 x 1 m). The representative material is installed over any patching compounds using the adhesive and techniques that are to be employed in the actual installation.

The test is conducted in tandem with the moisture testing to ensure that ambient conditions are appropriate for flooring installation. After the adhesives have cured for 72 hours, a razor knife is used to cut a 1 in. wide strip completely through the flooring and over the width of the sample. A crosscut is made in the middle of the strip, and a chisel is used to lift the strip sufficiently to allow the attachment of a clamp to the flooring material. The clamp is attached to a scale, and the maximum vertical force needed to peel the flooring from the slab is measured.

A minimum force of 10 lb (44 N) is required to indicate acceptable slab moisture conditions for most full-spread flooring systems (typically, rubber and vinyl) installed using a permanent adhesive (as opposed to a releasable adhesive, which allows flooring to be repositioned). Figure 2 shows a technician preparing to conduct a test on a flooring sample. Some WVRA manufacturers have compiled a historical library of appropriate pull strengths for common materials and adhesives.

Field Experiences

The following summaries highlight installations that used WVRA to prevent moisture problems.

The conversion of existing space in the Albany School of Medicine into a Level 3 biohazard lab required the installation of a raised area for two shower stalls. This required placement of a 4 in. concrete topping on an existing slab. A 4000 psi lightweight concrete mixture with 25% cement replacement with fly ash was specified. A WVRA was added to the mixture at a dosage of 62 fl oz/yd3 (2.4 L/m3). Seventeen days after the placement, heat-welded flooring was installed.

An addition to the Physics building at the State University of New York (SUNY) Sullivan also required the installation of heat-welded sheet flooring. The project’s floor slabs comprised a 3500 psi (24 MPa) mixture with a water-cementitious material ratio (w/cm) of 0.50. A WVRA was used at a dosage of 57 fl oz/yd3 (2.2 L/m3). The sheet flooring was installed only 7 days after concrete placement.

Additional Benefits

Using a WVRA can also boost the overall quality of concrete by providing an internal curing system. Curing maintains moisture and temperature conditions in freshly placed concrete and includes measures to modify the environment by limiting the loss of water.6 A properly formulated WVRA prevents moisture from leaving the concrete, and this shows in shrinkage tests.

Tests conducted per ASTM C157/C157M, “Standard and Test Method for Length Change of Hardened Hydraulic- Cement Mortar and Concrete,” have shown that a concrete mixture produced with a WVRA has 8% less shrinkage than the same mixture produced with a shrinkage-reducing admixture. The reduction in shrinkage also shows in the fact that slab curling and plastic shrinkage cracking are virtually eliminated in slabs containing WVRA.

Exterior concrete applications are further enhanced by the nearly impermeable concrete created by WVRA, dramatically reducing the ingress of deleterious chemicals. The reduced permeability can be shown using testing per ASTM C1202, “Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration.” However, just as with in-place moisture testing, test samples must be allowed to mature.

Conclusions

WVRA systems have made it possible to eliminate problems with moisture sensitive adhesives. Combined with the benefits provided by internal curing and greatly reduced permeability, WVRAs can be expected to be widely deployed to provide more resilient structures and pavements.

References

- “National Volatile Organic Compound Emission Standards for Architectural Coatings,” US Environmental Protection Agency (EPA), www.epa.gov/stationary-sources-air-pollution/architectural-coatingsnational- volatile-organic-compounds-emission.

- Hooulsby, A.C., Construction and Design of Cement Grouting: A Guide to Grouting in Rock Foundations, first edition, Wiley-Interscience, Hoboken, NJ 1990, 466 pp.

- Pelletier, M.M.; Brown, R.; Shukla, A.; and Bose, A., “Self-healing Concrete with a Microencapsulated Healing Agent,” http://energetics. chm.uri.edu/system/files/Self%20healing%20concrete%20-7-11.pdf.

- Thomas, J., and Jennings, H., “The Science of Concrete,” http://iti. northwestern.edu/cement/.

- Chen, J.J.; Thomas, J.J.; Taylor, H.F.W.; and Jennings, H.M., “Solubility and Structure of Calcium Silicate Hydrate,” Cement and Concrete Research, V. 34, No. 9, Sept. 2004, pp. 1499-1519.

- ACI Committee 308, “Guide to External Curing of Concrete (308R-16),” American Concrete Institute, Farmington Hills, MI, 2016, 36 pp.